GLASS/MIRROR FINISHES

EDGE PROFILES

When it comes to edge profiling glass and mirror, there are many options to consider and explore. While the primary purpose of edgework is to eliminate sharp edges for safety reasons, the various types of edging available can also elevate and accentuates the overall appearance of the glass. By refining the edges, it not only strengthens the glass’s structural integrity but also helps prevent chipping and ensures its durability. This meticulous attention to edgework detail adds aesthetic charm and enhances functionality and longevity, making it crucial in glass fabrication processes. See below for standard edge details, more options are available upon request.

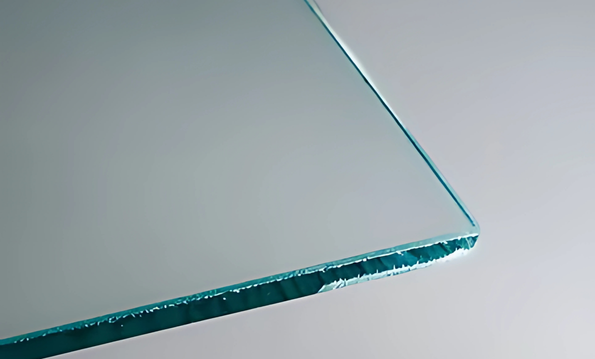

Arrised/Seamed Edge

Using a sanding belt, the edges of the glass are lightly sanded to produce a safety edge. These edges are used when edges are covered.

Applications: Millwork, cupboard doors etc.

Flat Ground Edge

Diamond embedded grinding wheels put a Satin finish on the edge, used when reduced reflectivity is require in the edges.

Applications: Glass floors, mirror etc.

Flat Polish Edge

High gloss finish used when edges are exposed.

Applications: Doors, partition walls, etc.

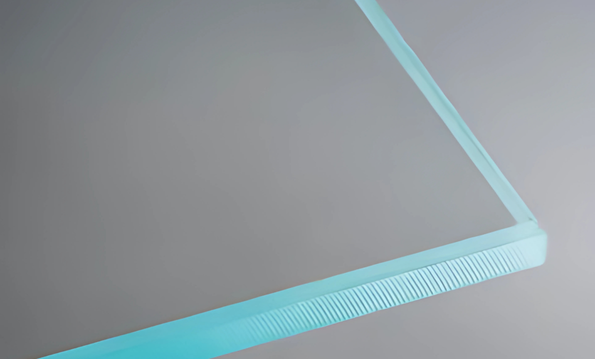

Pencil Ground Edge

Diamond embedded grinding wheels put a Satin finish on the edge radius in the shape of a C, used when reduced reflectivity is require in the edges.

Applications: Automotive, mirrors, etc.

Pencil Polished Edge

High gloss finish used in more decorative applications.

Application: Furniture, Mirrors etc.

CNC Polished Edge

High gloss finish used when tolerances are tight or on shapes

Applications: Railings, mirrors, feature walls etc.

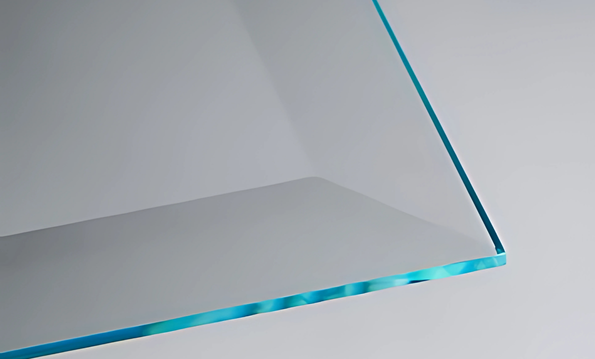

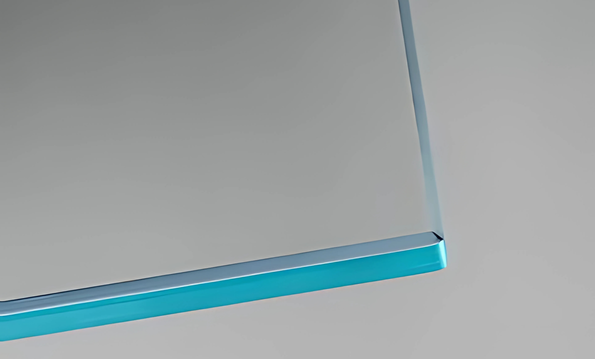

Mitred Edge

High gloss finish used in areas where glass meet at angles

Available in 22.5° or 45°

Applications: Showers, partition walls etc.

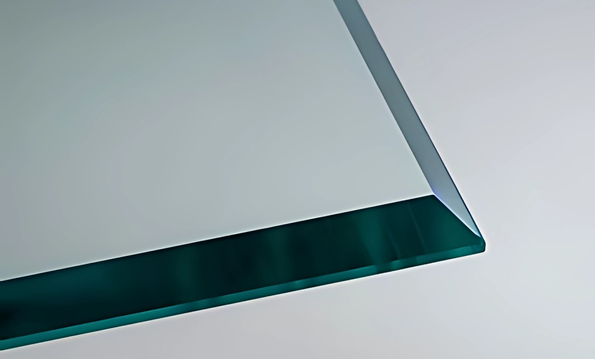

Straight Beveled Edge

High gloss or satin finish used to add aesthetics to a design

Available in ½”, ¾”, 1” and 1 ¼”

Applications: Mirrors, tabletops, etc.

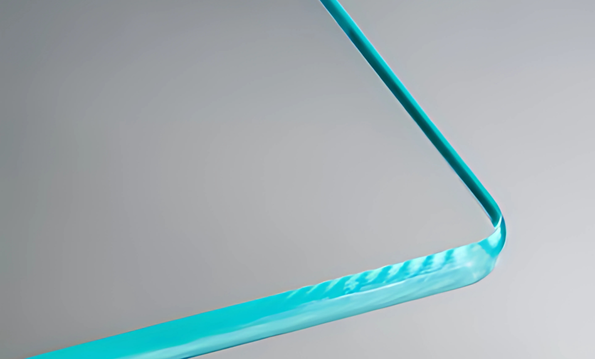

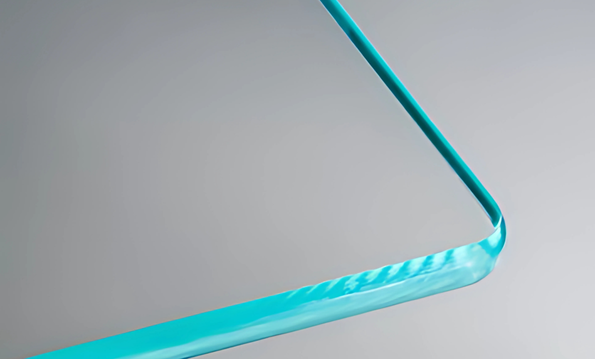

Shaped Beveled Edge

High gloss or satin finish used to add aesthetics to a design

Available in any sizes between ½” and 2 ½”

Applications: Mirrors, windows etc.

CORNER PROFILES

Standard Corner

A standard polished corner involves smoothing the edges of glass to achieve a clean and refined appearance; however, despite its commonality, it can pose a risk due to its sharp point on applications such as tabletops. Note: All glass will be fabricated with standard corners unless specified.

Dubbed Corner

Dubbed corners are created by lightly sanding off the sharp edge by hand, providing a safer alternative, although not as precise as radius corners.

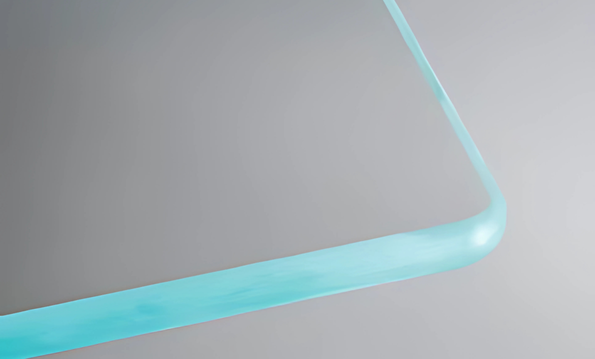

Radius Corner

Radius corners offer an ideal solution for enhancing both design aesthetics and safety, particularly for exposed corners in railings and tabletops. With sizes ranging from 1/8″ to 8″, they not only elevate the visual appeal of any space or design but also contribute to ensuring safety.